Solar thermal: A perfect fit for industrial heat decarbonisation

By Dr. Kristen Griffin, Chief Product Officer, 247solar, Inc

Long viewed as the troubled sibling of solar photovoltaic (PV) power, solar thermal power is now ready to take on the biggest prize of all – decarbonisation of industrial heat.

Over the past several decades, as demand accelerated for renewable energy, the need for technologies capable of delivering energy around the clock has become clear. Concentrated solar power (CSP) initially appeared to fit the bill. An array of mirrors focuses sunlight on a receiver at the top of a tower, which captures the solar energy as heat. This heat is either immediately converted to electricity using a turbine or stored for later use at night or during bad weather.

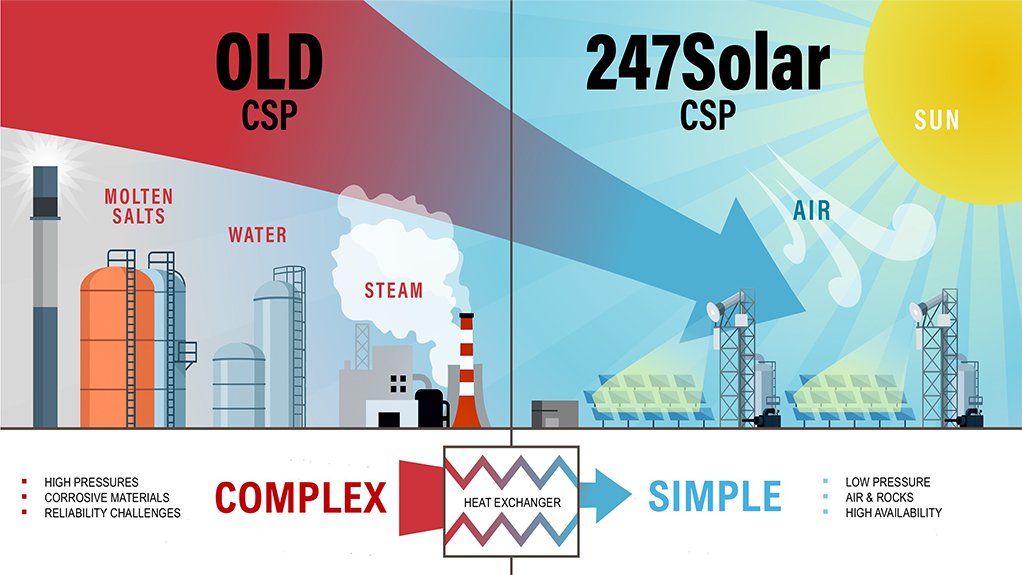

Unfortunately, the limitations of technologies available at the time drove a series of design choices that increased the complexity of the system, including the selection of steam turbines. The steam turbines were paired with molten salts as the most effective heat transfer fluid and thermal energy storage medium available at the time.

Traditional solar power towers have since been characterised by challenges with reliability, toxic leaks and an ability to provide energy only 60% of the time at a high cost.

Intermittent Renewables Prevail

Meanwhile, simpler renewables like solar PV and wind rapidly became more afford-able.

Yet they too were intermittent. Round-the-clock clean electricity remained a distant goal. Round-the-clock decarbonised heat was an even bigger challenge, earning the moniker “hard-to-abate,” because no solution based on solar PV or wind existed.

And so it was that even though traditional CSP had the ability to address the most pressing challenges of decarbonisation, it languished as a technology desperately in need of innovation.

As so often happens, the solution came from another scientific discipline entirely. An engineering lab at MIT was exploring applications for heat exchangers using newly developed high-temperature materials. The team, some of whom would go on to found modular concentrated solar energy system provider 247Solar Inc, envisioned using these materials for heat exchangers in air-based turbines to produce electricity.

The team realised that by transferring heat to the compressed air inside the turbine at a sufficiently high temperature (~1 000 oC), they could eliminate the turbine’s combustor and drive the turbine to produce electricity without steam or combustion. No water or fuel would be required, and no emissions would be produced. This single innovation eliminated the complexity that had plagued traditional CSP and birthed a new generation of simple solar thermal power.

Another advantage also emerged: the hot air flowing into the heat exchanger did not need to be pressurised. This meant that the entire system, including the receiver, could operate at atmospheric pressure. Once the receiver no longer needed to be an airtight pressure vessel, it was no longer limited to small sizes able to withstand high pressures and no longer required complex cooling systems, both of which had made prior air-based designs economically unviable.

In addition, the thermal storage could be a simple enclosure filled with inexpensive rocks, sand or ceramics rather than liquid-based systems, eliminating the limitations of traditional steam-based CSP.

How it Works

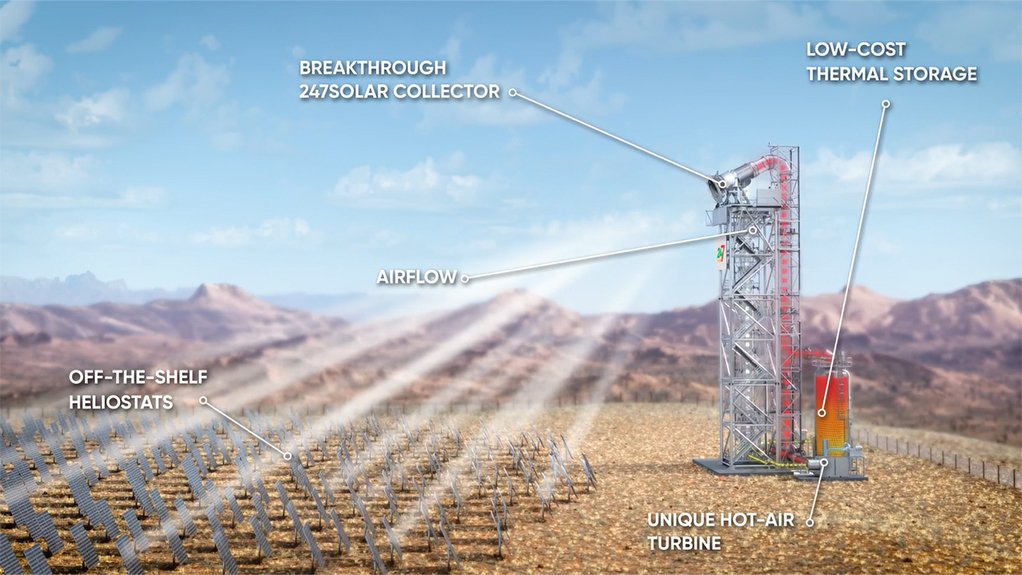

This next generation solar thermal plant is more like a wind turbine than traditional CSP in terms of few moving parts, design simplicity, and low risk to the environment. Like wind turbines, these modular systems can be deployed in any quantity to address the energy needs of a wide range of offtaker loads.

A receiver sits atop a tower, collecting sunlight from an array of mirrors and heating air that flows through it. The hot air can be directly provided to an offtaker for industrial processes, converted to electricity and medium-temperature heat by the turbine, and/or circulated through a thermal storage enclosure for later use. Because this system stores the sun’s energy as heat instead of electricity, no batteries are required, eliminating their costs and hazards.

This simple design provides high reliability and continuous operations through three unique features. With few moving parts and no liquid or steam, the system is easy to maintain and has an intrinsically low risk of failure. During maintenance, the modularity of the system virtually eliminates downtime; should one module be offline, the others are still available. Finally, the system includes its own backup; the turbines, by design, are capable of burning a variety of fuels to provide heat and power when neither sunlight nor stored heat are available.

Growing numbers of heat-only technologies are emerging for industrial decarbonisation, especially in relatively low temperature realms. The plant developed by 247Solar is the first to provide a comprehensive solution for both high temperature clean heat and electricity around the clock.

Prior to this innovation, commercial and industrial heat consumers were left out of the energy transition. At last, air-based concentrated solar thermal technology has arrived to decarbonise this critical sector, with simplicity, reliability and affordability that makes emissions from industrial heating no longer “hard to abate.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation